TrayHeart

Software TrayHeart

TrayHeart offers extensive possibilities for hydraulic calculations of tower trays (large variety of all aspects of tray designs), random packings, grid packings and structured packings, chimney trays, droplet separators, support grids, liquid distributors and various types of inlets.

The development of the software started in 1998 and was continued in cooperation with companies of the chemical industry and tower internals manufacturers. Today, it can be claimed as a state-of-the-art software to be able to compute all mass transfer equipment in detail. The following survey should help you to assess the scope of the software. If you have specific questions about database content, calculation possibilities, implemented models, designs and applications, please do not hesitate to get in contact with us (contact).

Please note: There is no demo version of TrayHeart. If you want to test the software, please contact us.

Contents

Program Modes

Single Design Mode

Liquid and gas are brought into contact at a so-called 'stage'. This contact takes place either on cross-flow trays (with different elements such as valves, bubble caps, sieve holes, etc.), in random or structured packings. This hardware is referred to as a 'Design' in TrayHeart. The Single Design Mode contains a maximum of two stream pairs and one Design.

Evaluation Mode

In order to validate model relationships, measurement data can be imported and statistically evaluated. This allows to check the suitability of models for specific application cases (e.g. for particular systems). Each measurement data point represents a fully defined single-stage design point (load, design) that is evaluated with the models and compared with the measured data. The calculated results are presented in tabular form or graphically (parity plot).

Profile Mode

The stream profile of an entire column is normally calculated by a thermodynamic simulator. These stream profile data can be imported into TrayHeart and assigned to corresponding designs. Depending on the application, these can include different tray designs, packings, internals, and other functional units (such as feeds, draws, distributors etc.).This allows for a detailed representation of the column, including nozzle positions, manholes, and special internals.

To compare different designs within a column, up to three different column configurations (e.g., 'As-Built' and revamp configurations) can be documented. Different operating modes (such as winter/summer operation or capacity increases) can also be managed in parallel.

In addition, the column can be visualized in both 2D and 3D graphics.

Trays

Tray Designs

TrayHeart can calculate basically all types of tray designs. In profile mode, different tray types can be combined, enabling calculation and analysis of the entire column. For each tray type, various models can be selected to calculate pressure drop, jet flood, system flood, choke flood, entrainment, and many other parameters. The following section outlines the different options for downcomer geometries (number of passes, downcomer geometry, weir types, downcomer outlet designs) and the configuration of the active area:

Flow Paths

Downcomer Layout

Outlet Weir Layouts

Additional features like weir spouts or anti-jump baffles are available, too.

Downcomer Inlet

Contact Elements

Sieve Trays

The sieve tray design can be defined by specifying relevant parameters such as the open area, rel. free area, number of holes and hole diameter.

Float Valve Trays (Movable Valves)

Movable valves can be selected from a comprehensive valve database, and the valve pitch can be defined by specifying parameters such as the number of valves, open area and valve opening. The database includes classic round and rectangular valves from various manufacturers, as well as cage valves and mini valves. Additionally, it is possible to define valve layouts with different valve weights ("multi-weight").

Fixed Valve Trays

The valve type can be selected from a large Fixed Valve database. By specifying parameters such as the number of valves and the free area (curtain area or panel area), the valve pitch is defined. The database includes round and trapezoidal valves from various manufacturers.

Bubble Cap Trays

Bubble cap geometries can either be defined directly or retrieved from the database. By specifying the open area, the number of bubble caps, the riser diameter,... the tray can be designed.

Tunnel Trays

The types Streuber (tunnels in flow direction) and Thormann (liquid meanders around the tunnels) can be calculated in TrayHeart. The tray is defined by specifying the tunnel geometry and orientation.

Proprietary Trays

A separate database contains designs such as Varioflex (VV12, VV16) and Bayer Bubble Caps. Special models for their hydraulic modeling are available.

Showerdecks / Baffle Trays / Sheddecks

Similar to the definition options for sieve trays, the perforation of shower decks can be specified. Baffle trays and sheddecks do not have any perforation.

Dualflow Trays

By indicating the free area, total hole area, rel. hole area, number of holes, hole diameter,... the Dualflow tray can be defined.

Liquid Distributors

TrayHeart can calculate all common liquid distributors. The types “pan type”, “trough type” and “deck type” represent the basic forms. Within these types of construction, the drip points can be defined as bottom hole openings, drip tubes, lateral openings and wall slots. Typical designs can be easily created by so-called shortcuts, but special designs can also be defined in great detail.

All distributors are shown as interactive 3D graphics. The liquid feed points can be visualized as a cone and the distribution image can be displayed in this way.

Pan Distributor

The basic dimensions of the pan distributor for small column diameters are defined by its diameter and height. Additional definition parameters include the annular gap, any additional open area placed as a gas chimney in the pan, as well as the liquid drip points (bottom openings, tubes with several levels of holes, wall holes with baffles).

Trough Distributor

The definition of trough distributors is based on templates (basic dimensions of the trough and its equipping with outlet openings). These are then assigned to the troughs in the layout and thus result in the distribution spectrum. Changes to the template have an immediate effect on the entire distribution layout. In addition, the pre-distribution (parting box and calming insert) can be designed.

Deck Distributor

Similar to the channel distributors, the deck distributor is defined using templates (basic dimensions of the chimneys and the type/position of outlet openings). These are then assigned to the layout and thus result in the distribution spectrum. Changes to the template have an immediate effect on the entire distribution list.

Distributor Performance

The distributor performance characteristic indicates the liquid level in the distributor for the entire range of possible load. The operating point, its stability and the operating performance of the distributor can be characterized on the basis of these characteristics.

Distributor Quality acc. to WelChem

The quality calculation based on the WelChem-TUM cell model is available for all distributors. The drip points are evaluated in the grid of the packing and an integral value is determined for the first, 10th and 100th layer. The quality value calculated in this way indicates the quality in relation to the bed.

Distributor Quality acc. to Moore&Rukovena

The quality calculation according to Moore&Rukovena is available for all distributors. With this model, an absolute quality index can be calculated.

Random, Structured and Grid Packings

Random Packings

There is a large variety of random packings. In the extensive database, 200 types are stored. The geometric characteristics, calculation parameters, mostly the photo and the interactive 3D model are stored for all packing elements.

Structured Packings

100 different types of structured packings are available in the database. The geometrical parameters and calculation parameters are stored accordingly.

Grid Packings

Robust structures for heat and mass transfer as well as particle/droplet separation are referred to as grid packings. There are 15 different types available in the database. The geometrical parameters and calculation parameters as well as a photo are stored.

Support and Hold-down Grids

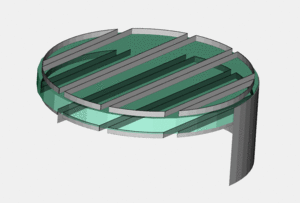

Multibeam Support Grid

Multibeam support grids are normally used for random packing, as they can achieve a relative opening area of 100%. The basis for the static calculation is the specification of the supported packing (type of packing, material, bed height, hold-up). Different standard geometries for the profile dimensions can be taken from shortcut buttons.

Hold-down Grid

In order to prevent random packing elements from moving or from being thrown into the distributor, hold-down grids are placed on the bed.

Flat Support Grid

Flat support grids are used for structured packings. The basis for the static calculation is the specification of the supported packing (type, material, bed height, hold-up).

Intakes, Feeds

The intake of gas or gas/liquid into the column can take place in different systems, depending on the volume flow and phase proportion of the liquid. In TrayHeart, simple V-Baffles, pipe inlets (I-pipe, T-pipe, H-pipe, ladder-type systems, half-open pipes) and vane type inlet systems (e.g. “Schoepentoeter”, “EvenFlow”) can be calculated.

Wire Mesh Droplet Separators

TrayHeart offers extensive possibilities for calculating the separation efficiency of wire mesh droplet separators. The basis for this is the database with different wire mesh types (mesh density, wire diameter, wire material).

The input data for the calculation is the droplet spectrum (direct input for up to 20 droplet classes or calculated as normal distribution from a given mean droplet diameter). The wire mesh can be defined from up to 3 different mesh layers. For each droplet class the separation efficiency is calculated, as well as the overall efficiency.

Databases

Movable Valve Database

The database for movable valves includes the conventional and historical designs (for recalculating existing systems). These include round and rectangular as well as caged valves in different dimensions from well-known manufacturers.

Fixed Valve Database

The Fixed Valve database includes the configurations of the fixed valve: round (e.g., VG0 and VG10) or trapezoidal (e.g., MVG and MMVG) elements, as well as covered openings (such as ProValve).

Bubble Cap Database

The dimensions and design of the skirts of bubble caps as well as their risers are stored in the bubble cap database (user can add new data sets).

Proprietary Design Database

The proprietary design database contains elements which can not be specified as a cage valve or bubble cap (such as Varioflex, Bayer Flachglocke). A 3D representation is available for these designs.

Random, Structured and Grid Packing Database

More than 300 elements from a wide range of manufacturers are available in the random packing, structured packing and grids database. Many of the entries support a 3D graphics of the component and a photo.

Distributor Database

Standard designs of distributors are stored in the distributor database (freely expandable). Using these templates, distributors can be quickly designed.

Check Database

Queries are stored in the check database, which are used to check results. This allows the user to incorporate his own KnowHow and to link notifications and error messages to corresponding (design-specific) conditions. The program is also supplied with a comprehensive internal database for check queries. (See detailed description below at 'calculation').

Material Database

The material database contains about 50 materials with their physical parameters (modulus of elasticity, yield strength, ...). These material data is the basis for the strength and vibration calculation.

Wire Mesh Database

In the wire mesh database, material parameters (wire mesh density, material, wire diameter) from different suppliers are listed. This data is the basis of the droplet separator calculation.

Calculation

TrayHeart is based on a very powerful calculation engine for the hydraulics of all designs. Models developed by WelChem are available for several parameters. Users can use the default models or they can define their favorite model set.

FRI Calculation Models

Members of the FRI (Fractionation Research, Inc. – Stillwater USA) can use the implemented models of the design manuals and topical reports.

Members of the FRI (Fractionation Research, Inc. – Stillwater USA) can use the implemented models of the design manuals and topical reports.

Strength Calculation

The static calculation of the trays is always running in the background. This ensures that these aspects (height of stiffeners, max. width of panels, manhole diameters, influence of beams, …) are taken into account and the result of a design calculation is realistic.

The static calculation of the trays is always running in the background. This ensures that these aspects (height of stiffeners, max. width of panels, manhole diameters, influence of beams, …) are taken into account and the result of a design calculation is realistic.

In order to recognize the dangers of vibrations and the resulting defects, natural and excitation frequencies are also calculated and corresponding warnings are issued.

Checks

Each design has about 100 geometric and hydraulic parameters which are checked for plausibility by TrayHeart. To do this, there are always hundreds of queries checked in the background that indicate input errors, unusual values, exceeding limits, problems with feasibility on the production side, or model limits. These check queries are based on literature, best-practice, presentations, physical limits and expert know-how.

These messages are displayed in the sub-dialogs as well as on the main screen as entries in the journal window, marked by highlighting the relevant values and color background in the input cells.

These messages are displayed in the sub-dialogs as well as on the main screen as entries in the journal window, marked by highlighting the relevant values and color background in the input cells.

TrayHeart uses a total of more than 1000 check queries for the various types. The user can define additional know-how in their own check databases (In this way, the company’s own know-how on applications and internals can be secured and made available to a group of users). All queries are carried out simultaneously and lead to corresponding hints, warnings and error messages.

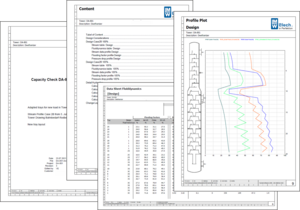

Results

The design and calculation results can be displayed as table and graphically. All printouts can be supplemented with your own company logo.

The language (German or English) as well as the unit set used (SI, US, adapted SI, user-specific) can be set for all outputs.

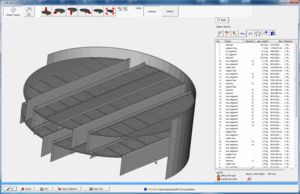

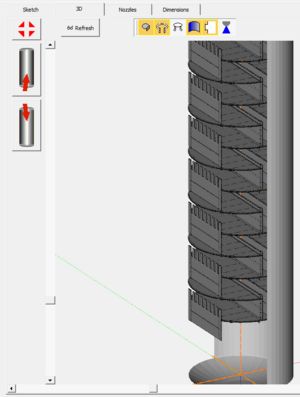

3D Graphics

All designs are displayed as interactive 3D graphics. This graphic is scalable, rotatable and zoomable and provides a good guide to practicability. In addition to the visual assessment, the representation of neighboring stages gives hints about problems with accessibility and assembly. All parts are shown in a list with main dimension and weight.

Result Graphs

Different graphic evaluations are available, such as operation diagram, liquid distributor characteristic, valve characteristic (multi-weight valve trays), liquid distributor quality, hydraulic gradient.

Profile Graphs

Entire columns can be calculated in the profile mode. Flow profiles, pressure drop profiles, load profiles, ... can be plotted vs. height (elevation). These graphics are also available on the main screen as well as for printout.

Summary Output (Reports)

For the documentation of the results, different printout options are available. The individual printouts can be bundled to a summary output (report). A report can be created by corresponding additional pages (title, table of contents, calculation models, ...). The structure of this summary output is stored in the calculation file and can be - e.g. after revisions - generated again easily. The input and calculated values can be saved as a file export (ASCII) or can be exported to Excel.

3D Tower Graphics

The structure of a complete column can be defined in the profile mode. The column structure is created by assigning the designs to the stages of the stream profile. By assigning the nozzles and their position (orientation, elevation), the position or collisions between the internals and the nozzles (sensors, feeds, ...) can be seen immediately in the 3D view. Since the nozzle table can be imported, revisions can be easily checked during the project progress.

Tools

Additional to the calculation of trays and internals, there are several helpful tools: Two-Phase Flow Pattern Maps, Calculation of filling and draining rates of columns during pressure tests, as well as the effects of tray inclination.

Manual

The manual describes the operation, equipment characteristics and the calculation bases on about 700 pages. Help functions access the appropriate pages in the manual.

Training

Regular webinars are dedicated to one topic at a time. The basics of design types (trays and internals) are described, as well as the procedure for calculation in TrayHeart. All licensees can participate in these webinars. For subscribe / unsubscribe to invitation maillist please mail to webinar@welchem.com

For specific training requests, customized webinars for your company can also be arranged.

Licensing of TrayHeart

There are different license models available for TrayHeart. These depend on the number of users, the scope of functions and the duration of the license.

Reference list

TrayHeart is used by chemical, petrochemical, engineering companies, refineries and suppliers of trays and tower internals.